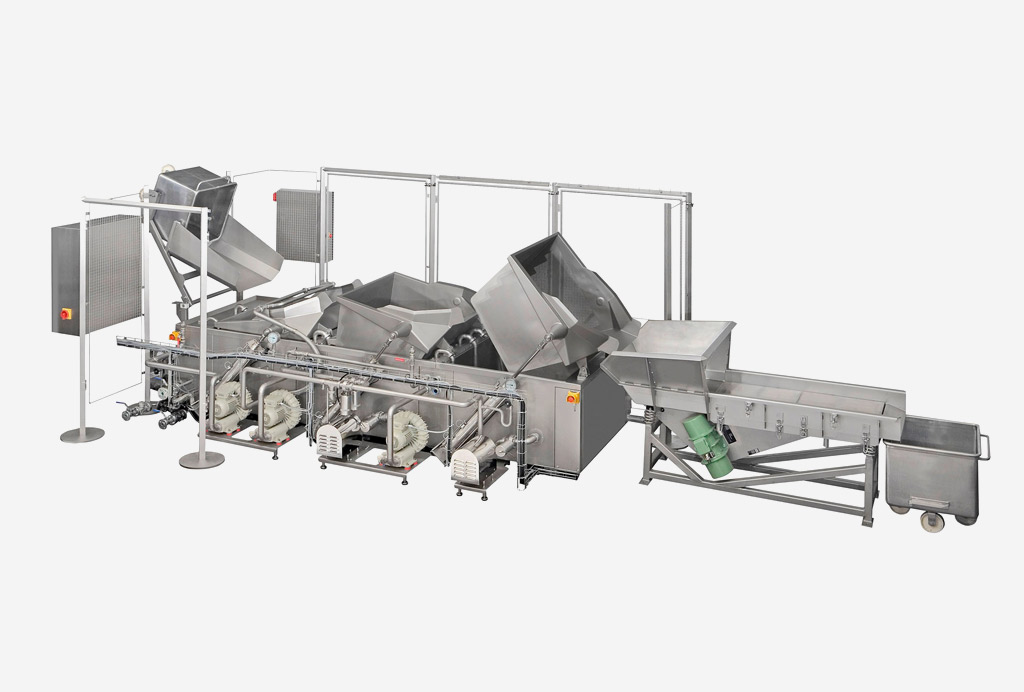

Boiling Kettle with Tiltable Basket HODAKO-S

-

A key success factor for industrial kitchens is the efficient flexibility, especially when it comes to the production of small batches. Mainly in the field of Ready-to-Serve-Meal industry it is often not worth using continuous systems. The cooking kettle with slewing basket type HODAKO-S offers the possibility to add small amounts to blanch quickly and inexpensively or cook. Especially be very fast heating provides the necessary flexibility in a kitchen. This is achieved by the heating with high pressure steam. Through a cascade formation, several boilers a cooking-cooling process can be made. Here, a boiler is used as a cooking kettle and the following used as a cooling vessel. The cooling is carried out directly by the fresh and / or chilled water. is emptied into standard car.

Perfect for blanching, boiling or cooking of

- rice

- pasta products

- meat, fish, seafood

- vegetables

- fruits

- potatoes

- other food stuff,

which have to be cooked in water or broth

Equipment and options

- heavy duty construction made from stainless steel

- heating with high pressure steam up to 5 bar

- swiveling, perforated basket, standard perforation 4 mm

- pneumatic actuation of the basket

- perforation according to product needs

- temperature controller and timer

- infeed for cold or hot water

- swing-loader for loading of product into the kettle

- air bubbling system for product movement

- water rinsing system at basket

- Standard sizes: 500 or 1.000 liter boiler, basket 350 or 700 liter total volume

- cascade 2 or 3 times – HODAKO-S-2 / HODAKO-S-3

Extended models as cooking-cooling system

- set up in a row – cooking kettle with one or two cooling kettles

- filling using a swing-loader

- drainage via vibrating trough

- cooling with fresh and / or cooling water

- air bubbling system for product movement

- manual or automatic movement of the baskets

- automatic, semi-continuous working system